You will not be allowed to compare more than 4 products at a time

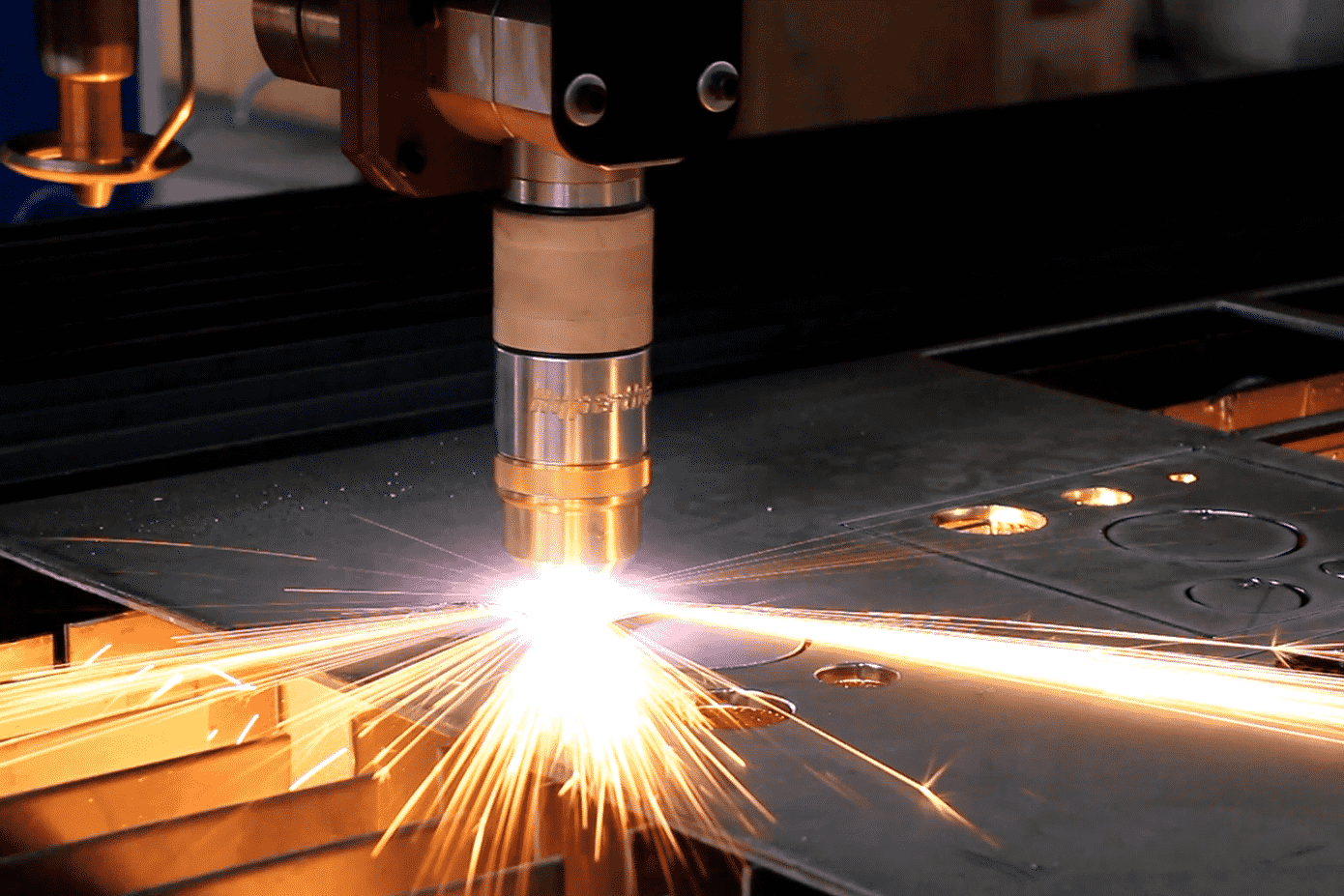

View compareFULL FABRICATION SERVICES

Transforming Ideas Into Precision-Engineered Parts

30+ YEARS EXPERIENCE

Where Custom Concepts Meet Expert Design

FULL FABRICATION SERVICES

Transforming Ideas Into Precision-Engineered Parts

30+ YEARS EXPERIENCE

Where Custom Concepts Meet Expert Design

Our process

Trust us to handle every step of your project with precision, quality, and reliability.

FAQ

Discover Solutions

What industries do you serve?

We specialize in serving the locomotive, manufacturing,U.S. Military, industrial, and robotics industries. However, our expertise extends to any project requiring precision metal fabrication, painting, welding, or 3D scanning.

Can you handle custom projects?

Absolutely. From initial CAD designs to final finishing, we excel in creating custom solutions tailored to your exact specifications and industry requirements.

Do you offer mobile welding services?

Yes, we provide mobile welding and on-site fabrication services. This allows us to bring expert solutions directly to your location, minimizing downtime and keeping your project on track.

What is 3D scanning, and how can it help my project?

3D scanning allows us to capture precise measurements of existing parts or structures. This data is used for reverse engineering, quality control, or creating accurate CAD models for new fabrication.

What type of coatings do you offer for industrial painting?

We offer high-performance coatings designed for durability and resistance to harsh conditions, including high-heat environments and exposure to saltwater.

Can you handle large-scale industrial projects?

Yes, our team and facilities are equipped to manage large-scale projects, from locomotive components to heavy machinery and structural fabrication. Let us know your requirements, and we’ll tailor our services to meet your needs.

What does your fabrication process look like from start to finish?

Our process begins with precise CAD designs and 3D scanning to ensure accuracy. Next, we handle fabrication using advanced techniques and high-quality materials. We finish with industrial painting or blasting for durability, and finally, provide seamless delivery or on-site installation for a complete solution.

How do you ensure the durability of your industrial paint jobs?

We use advanced surface preparation techniques, including blasting, to ensure proper adhesion, followed by high-performance coatings tailored to withstand harsh industrial environments like high heat, heavy wear, and exposure to corrosive elements.

insta-gallery

Get to See what we do